Artists, Photographers & Crayon Scribblers Wanted!

The Clark Fork Watershed Education Program (CFWEP) and Butte-Silver Bow have teamed up to increase stormwater awareness in our community by placing public art on traffic signal boxes throughout Butte. Community members often don’t realize that all of Butte’s stormwater is untreated and eventually makes its way into either Blacktail or Silver Bow Creek. Unfortunately, this means trash, oil, and other materials make their way into these important bodies of water threatening the health of our precious water resources. The goal of this effort is to increase awareness of storm drain connections to our creeks while adding vibrancy to our community through public art installations (cfwep.org).

Here’s where you, your kids, family members and friends come in—we need artwork/photos!

WET is sponsoring four (4) traffic signal boxes in Butte that will be wrapped in artwork. If you would like to submit something, we will be accepting artwork until August 19, 2019. See artwork submission details below.

The winner will get their…

-Artwork displayed on a traffic signal box

-Name on a plaque at the traffic signal box location

-Photo taken with their traffic box to be placed on the CFWEP website

-Artwork showcased on WET’s social media sites

ALL ages and all artwork types welcome!

Artwork theme: ecological, aquatic, or riparian connectedness theme—honoring the unique ecology and beauty of the summit valley, our water resources, and the outdoor areas we all know and love.

___________________________________________________________________

Please submit artwork along with your name, phone, email, and artwork details.

Submit Digital Art: Email art to Kali Cummings at kcummings@waterenvtech.com.

Submit Hardcopy Art: Deliver or mail art to Water & Environmental Technologies (WET) | ATTN: Kali Cummings | Marketing Specialist | 480 East Park Street | Butte, MT 59701

If you have questions, please contact Kali at (406) 723-1530 or kcummings@waterenvtech.com.

Photos and artwork must be an original creation—no copyrighted art or photos may be used. WET is not responsible for intellectual property violations that might have resulted through the submissions of art or photos.

Winners

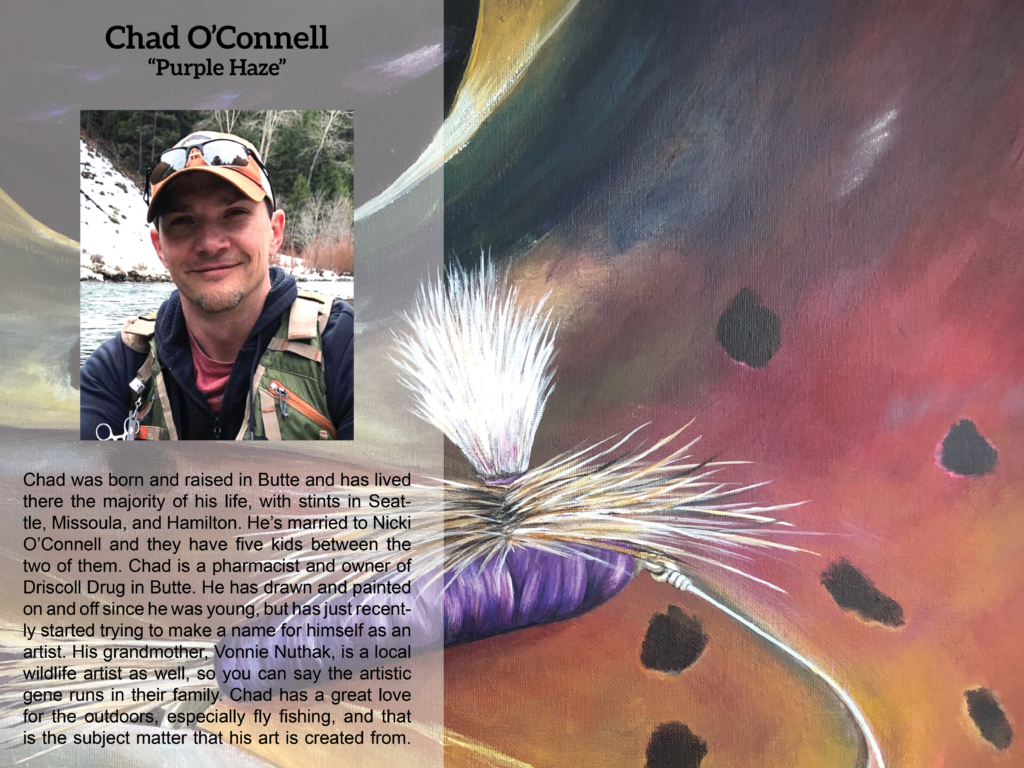

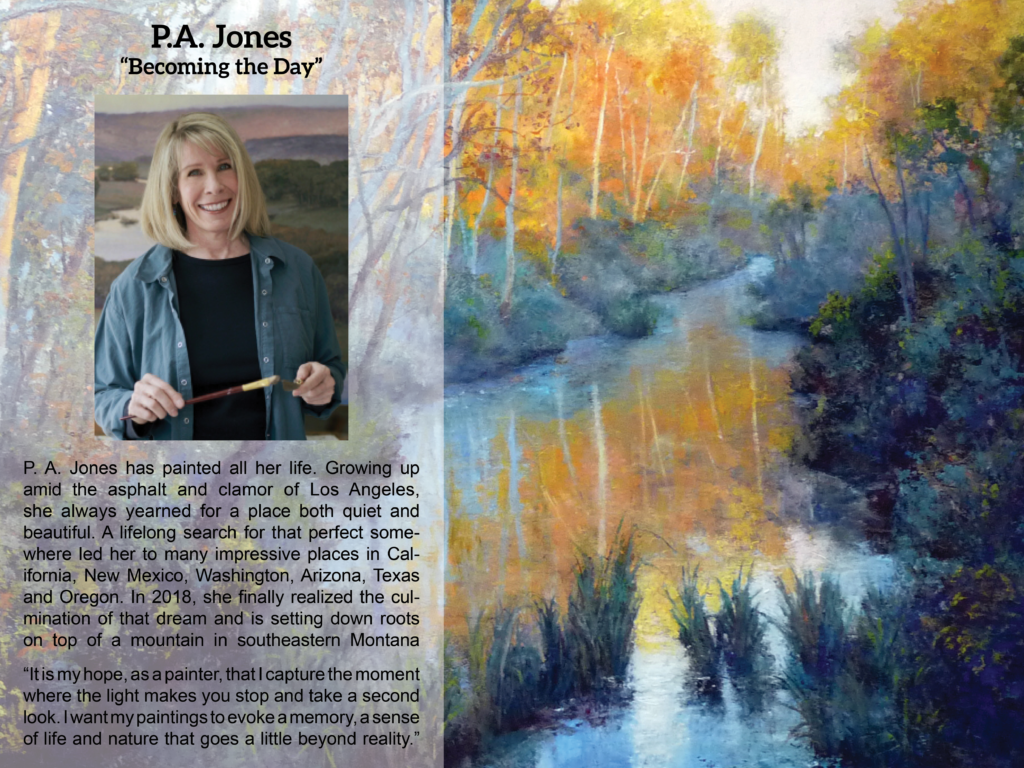

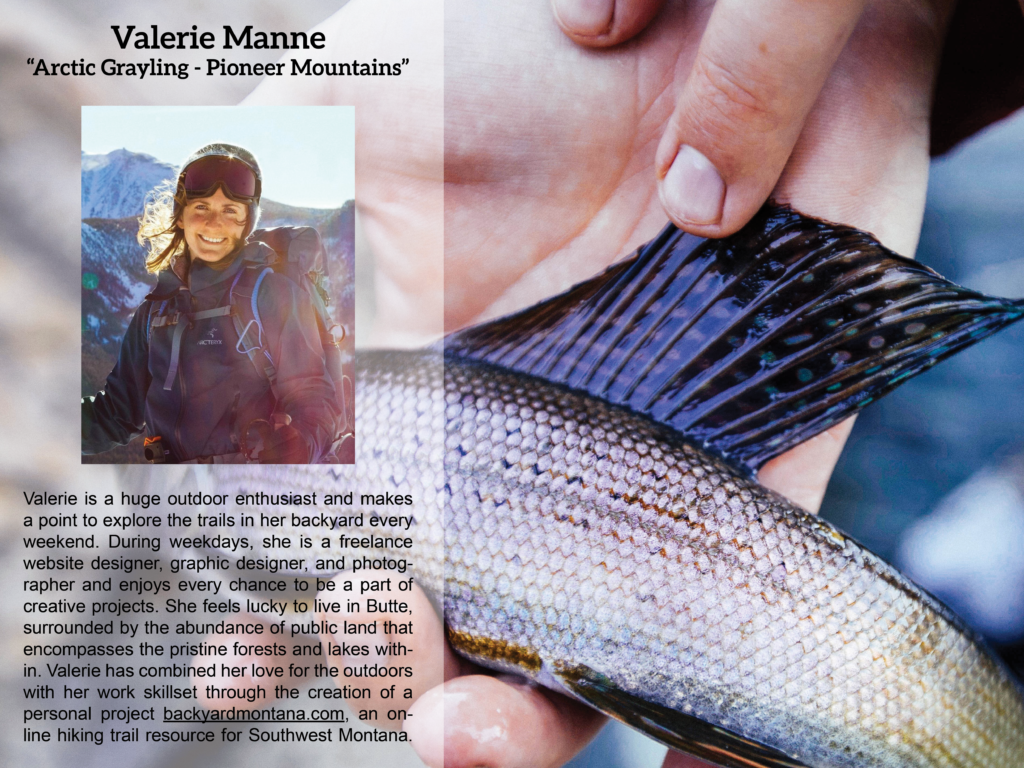

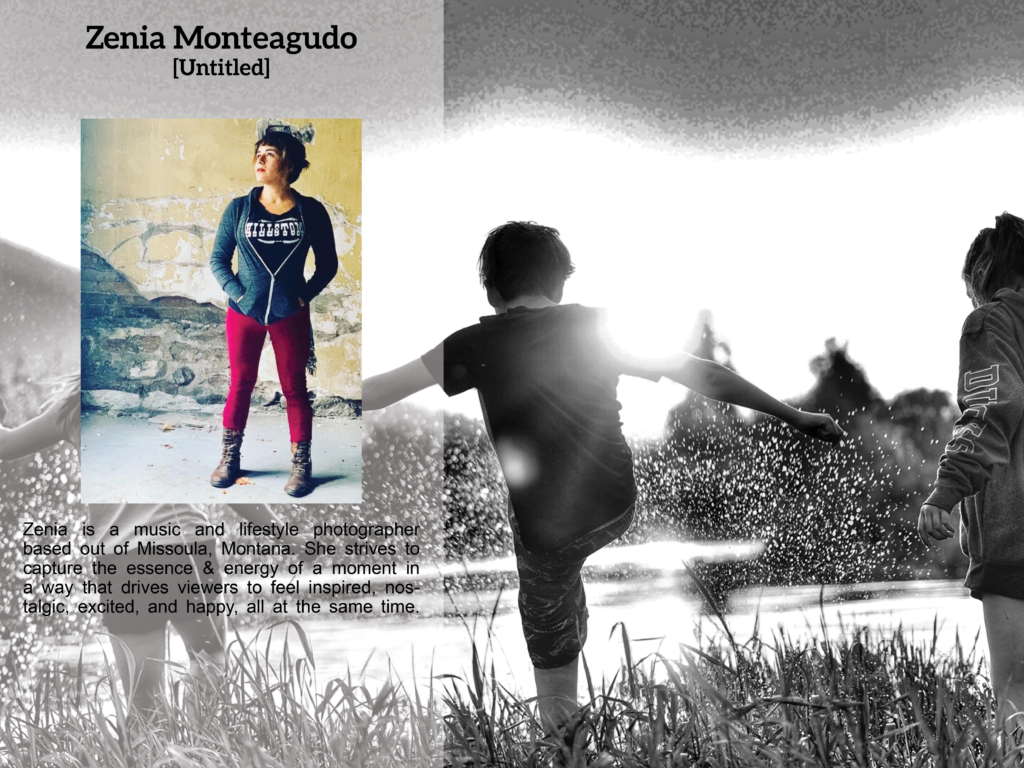

Congratulations to our four winners, Chad O’Connell, P.A. Jones, Valerie Manne, and Zenia Monteagudo! Stay tuned for more updates and images as these works of art get wrapped around Butte traffic signal boxes.

Last month, Water & Environmental Technologies (WET) welcomed Stephen Coe to the Permitting and Engineering teams. Stephen joined the WET team as a Senior Engineer who will be providing project management and technical expertise, while primarily focusing on developing air quality services within WET. Stephen has a Bachelor of Science in Environmental Engineering and 26 years of industry experience.

When constructing a new industrial facility, expanding production, or modifying operations, owners/operators and facilities may be subject to air quality permitting requirements. Sources must be designed, constructed, and operated to comply with all applicable air quality regulations. Air quality requirements exist within a range of regulatory programs, including state/local, and federal programs such as New Source Review (NSR) and Title V operating permit programs. Technical requirements such as emissions quantification, control technology evaluations, air quality analysis (including dispersion modeling), ambient air and meteorological monitoring, emission standards applicability, and compliance assurance are all components of these regulations.

WET can assist with all phases of the air permitting process, assuring accurate, timely permit applications that are focused on maximum operational flexibility. Expert negotiations with regulatory agencies simplify the permitting process.

To learn more about all of our air quality services and to request a quote, visit our Air Quality Services Page and download the flyer.

Since its inception in 2000, WET has grown from a highly specialized group of groundwater professionals into a full-service environmental and engineering consulting firm with office locations in Anaconda, Bozeman, Butte (headquarters), Great Falls, Helena, Kalispell, and Missoula, Montana and Sheridan and Worland, Wyoming.